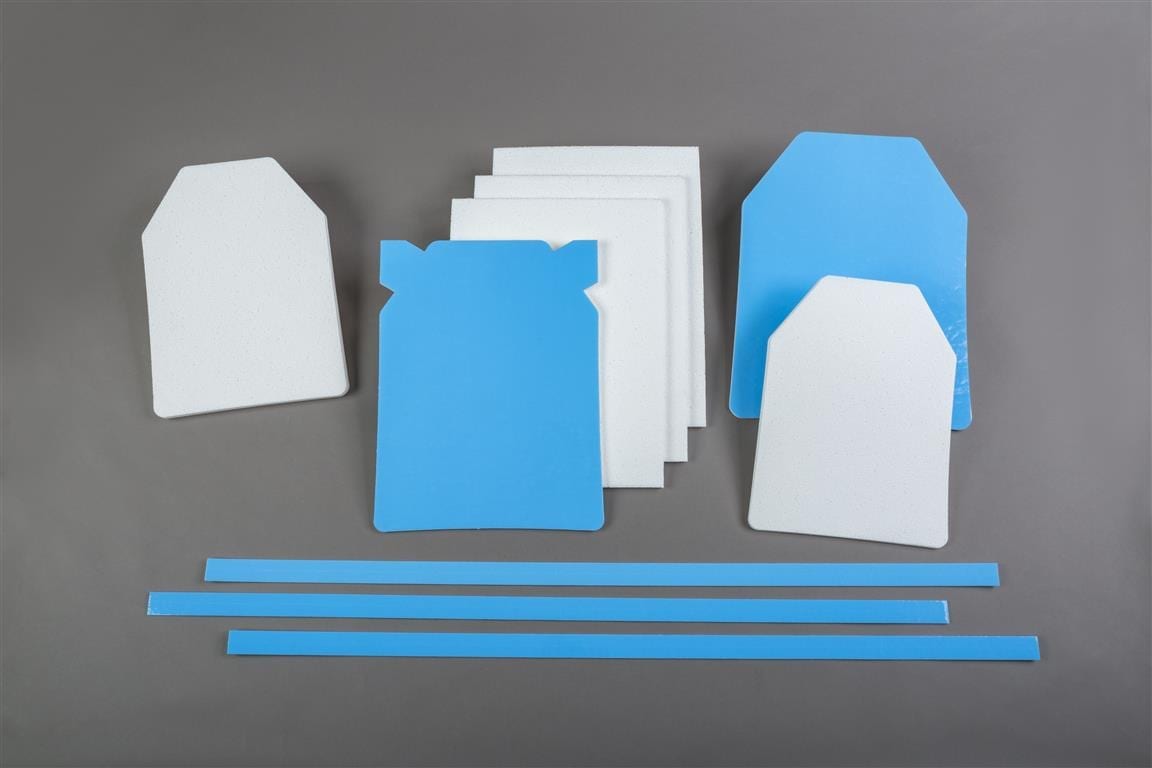

AR1300 ARMA – STRIKE

Foam protection

for Body Armor Plates

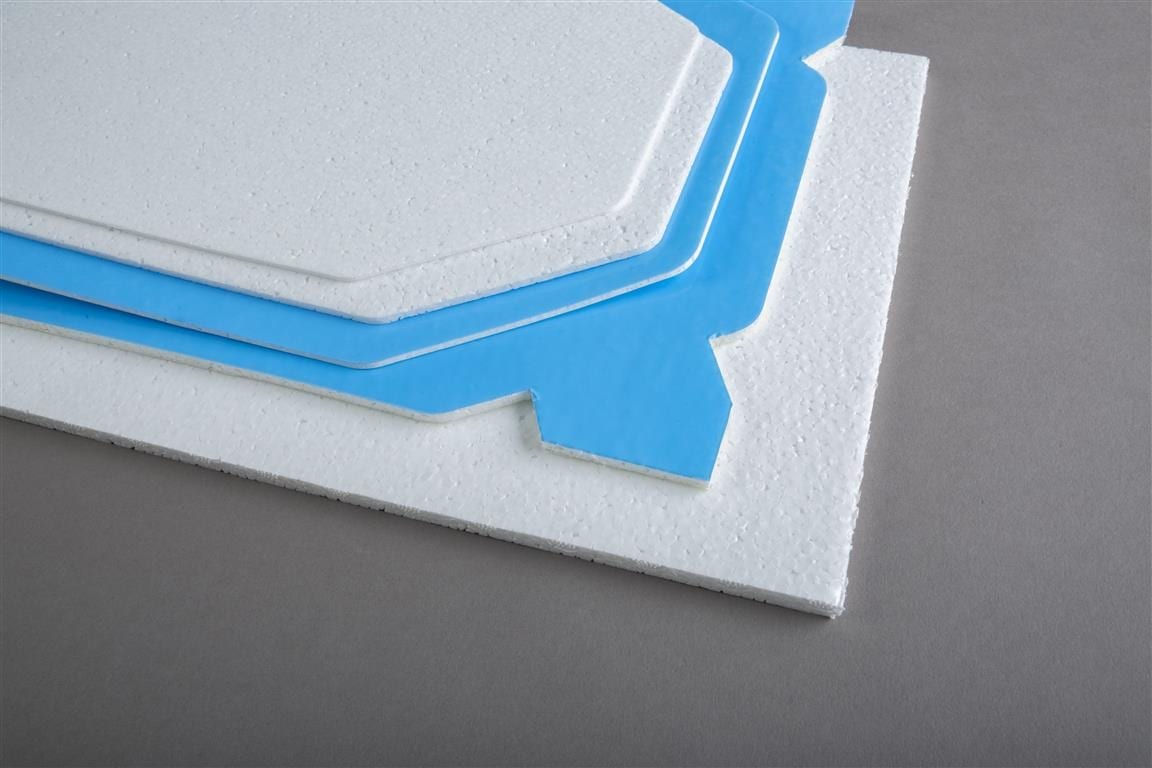

ARMA – Strike is a resilient expanded polyethylene (EPE) energy absorbing foam for applications requiring impact absorption, vibration dampening, insulation, buoyancy and chemical resistance. ARMA-STRIKE is ideally suited for front, back and side body armor applications.

At 4.2lb density, ARMA-STRIKE is lighter and more durable than many other body armor foams available while delivering excellent impact protection.

- Available with or without (PSA) pressure

Sensitive Adhesive - High surface energy bonds very well with PSA

- Available sheet or diecut shapes

- Skived to any thickness from .050″ to 5.00″

- Meets Mil Spec CID-A-A-59136. No off gassing

to comply with less than 10% LEL.

Other Foams Available:

(All available with or without PSA and in sheet, roll or diecut form)

PORON® – Cellular urethane foam, various thicknesses, density/hardness and grades including Poron XRD.

VOLARA® – Cross linked polyethylene foam in various thicknesses (2lb – 4lb and 6lb densities) in white or black color

BROCK® – 5.1lb density EPP foam available in various thicknesses.

Description

is a resilient expanded polyethylene (EPE) energy absorbing material for applications requiring impact absorption, vibration dampening, insulation, buoyancy and chemical resistance. Our technology ius ideally suited for front and back body armor applications.

At 4.2lb Density, is lighter and more durable than many other body armor foams in the marketplace while delivering excellent impact protection.

is available with (or without) our pre-applied Pressure Sensitive Adhesive (PSA). The PSA feature allows increased productivity with exacting control and cost.

For additional speed enhancements, can be cut to exact dimensions and delivered to fit your design criteria

MILITARY – Meets MIL Spec CID-A-A-59136. No off-gassing to comply with less than 10% LEL.

| Physical Properties | Test Method | Units | Values | Values |

| Density (Grade) | ASTM-D3575 | pcf | 4.2 | (+/-10) |

| Density | ASTM-D3575 | g/l | 67 | |

| Compressive Strength @ 10% | ASTM-D3575 | psi | 29.4 | 26 psi min |

| Compressive Strength @ 25% | ASTM-D3575 | psi | 35.7 | 32 psi min |

| Compressive Strength @ 50% | ASTM-D3575 | psi | 56 | 50 psi min |

| Compressive Strength @ 75% | ASTM-D3575 | psi | 1136 | 101 psi min |

| Tensile Strength | ASTM-D3575 | psi | 98 | 87.5% min |

| Tensile Elongation | ASTM-D3575 | % | 22 | 20% min |

| Tear Strength | ASTM-D3575 | lbs/in | 28 | 25 psi min |

| Compressive Set @ 25% | ASTM-D3575 | % | 7 | 8% min |

| Compressive Set @ 50% | ASTM-D3575 | % | 15 | 17% min |

| Buoyancy | ASTM-D3575 | lbs/ft3 | 57.5 | |

| Thermal Conductivity | ASTM-C177 | (K) BTU-in/ft2-hr°F | 0.28 | |

| Thermal Resistance | ASTM-C177 | (R) @70°F | 3.6 | 3.2 min |

| Coeff. Of Lin. | ASTM-D696 | in/in/°F x 10-5 | 4.2 | |

| Service Temperature | ASTM-D3575 | °F(MAX) | 160 | |

| Water Absorption | ASTM-3575/C272 | %(vol)/lb/ft2 | <5.0/<0.02 | |

| Compressive Creep | ASTM-3575 | 1000hr, % (psi) | 5.5 (10) | |

| Flammability | FMVSS-302 | <4.0 in/min | Pass | |

| Chemical Resistance | Various | 1 hr exposure | Pass | |

| Fuel Immersion | Coast Guard; Fuel B | <5% (chg in vol) | NA |

03-2015-A

Important Notice: All statements, technical information and recommendations related to the Seller’s products are based on information believed to be reliable, but accuracy or completeness thereof is not guaranteed. Before utilizing the product, the user should determine the suitability of the product for its intended use. The user assumes all risk and liability whatsoever in connection with such use. Arma Products™ makes no warranties, expressed or implied, of merchantability or fitness for a particular purpose.

armaproducts.net